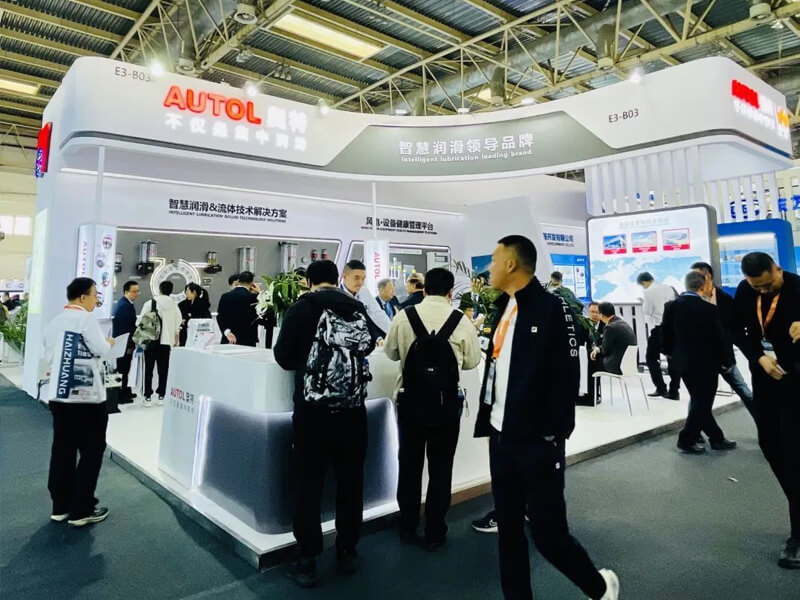

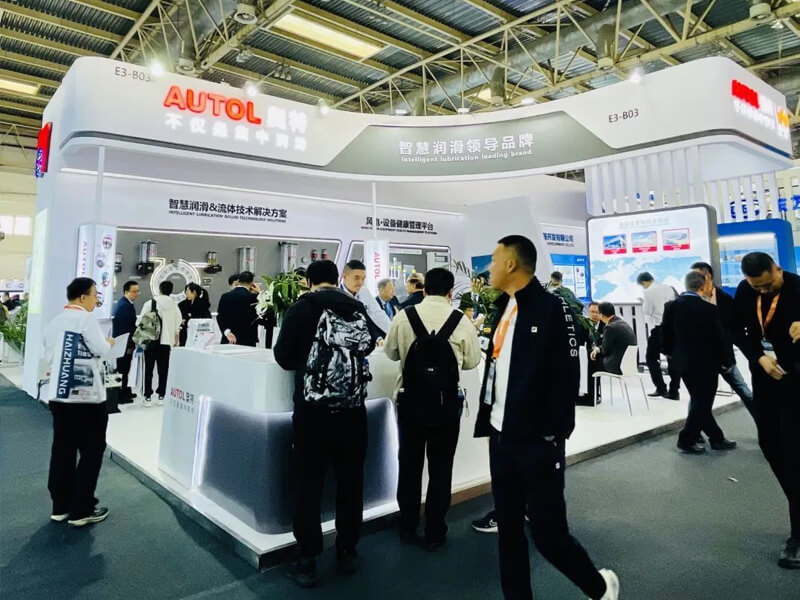

On October 17-19, the 2023 Beijing International Wind Energy Conference and Exhibition was grandly opened at the China International Exhibition Center (New Hall). Zhengzhou Autol Technology will bring a full range of wind power intelligent lubrication products, focusing on the theme of "full life cycle service of wind power equipment health management", from intelligent lubrication & fluid technology solutions to wind power equipment health management platform, to help customers achieve fault diagnosis, predictive maintenance, reduce unplanned downtime, ensure the health and reliability of bearings, and help wind turbines reduce costs and increase efficiency.

As the innovation leader and international pioneer of China's centralized lubrication industry, Zhengzhou Autol Technology Co., Ltd. was criticized by the Ministry of Industry and Information Technology as a specialized, special and new key "little giant" enterprise, with academician workstation, German Lubmann GmbH R&D platform, testing center has passed the national CNAS laboratory accreditation, has applied for more than 300 domestic and foreign patents, intelligent lubrication products are widely used in wind power generation, construction machinery, commercial vehicles, iron and steel metallurgy, port equipment and other fields, global marketing service network, Provide customers with leading equipment lubrication solutions!

· Intelligent lubrication & fluid technology solutions

The intelligent lubrication system is composed of a centralized lubrication system, an active grease removal system, a Schaeffler grease sensor and an online lubrication evaluation system, which is a set of on-demand lubrication based on monitoring the condition of the grease during the operation of the rolling bearing. The change of lubrication state usually precedes the occurrence of early bearing failure, once the abnormality is found, timely intervention can be carried out to eliminate potential risks, extend equipment life, improve bearing health, extend bearing service life, and improve power generation and owner profitability.

· Wind power equipment health management platform

This year, as the authorized distributor of Schaeffler, the world's leading bearing company, Autol exhibited Schaeffler's wind power equipment health management platform. By monitoring the high-risk factors in the operating environment of the fan, real-time monitoring of the bearing grease status, radial/axial vibration, temperature/humidity, shaft voltage and other states, the status identification and evaluation of the equipment can be realized, and the abnormal situation of the equipment can be automatically alarmed and early diagnosed, the development trend of the equipment can be predicted, and the high-risk factors can be eliminated or reduced, so as to avoid the early failure of the bearing, which can significantly reduce unplanned downtime, improve efficiency, reduce operation and maintenance costs, and escort the operation and maintenance of wind turbine equipment.

In the future, AUTOL will continue to uphold the service concept of "customer-centric" and actively respond to the "30 · 60" calls for the goal of carbon peak and carbon neutrality, focuses on the development of innovative technologies, takes the healthy and efficient operation of wind power equipment as its own responsibility, adheres to green, low-carbon and sustainable, and helps the wind power industry to achieve a better future together!