| Product Picture |

|

|

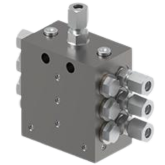

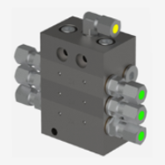

| Model |

SSVA |

JPQ |

| Operating Temperature |

T -40 °C~80°C |

T -40 °C~80°C |

| Outlet Flow |

0.2 ml/cy |

0.08, 0.16, 0.24, 0.32ml/cy

0.8, 1.04,1.28,1.6ml/cy |

| Number of Outlets |

6-22 outlets |

6-24 outlets |

| Operating Pressure |

35 MPa |

30 MPa |

| Applicable Grease |

NLGI-0#,1#,2# |

NLGI-0#,1#,2# |

| Inlet/outlet Thread |

M10 x 1 |

M10 x 1 |

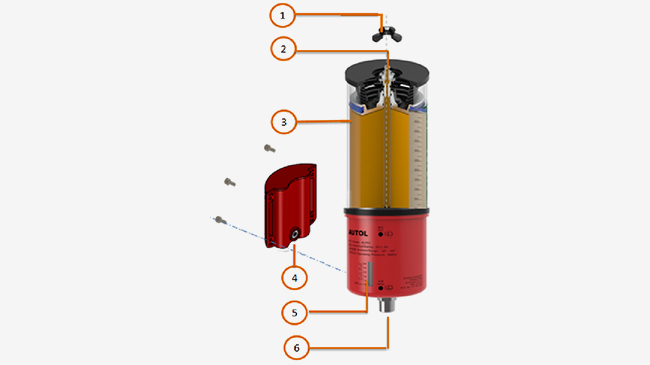

Higher work pressure

• The quality of fit of the pump element piston pair reaches μm class and the max operation pressure is up to 4MPa.

•It can work with 8-hole progressive distributor to supply grease to multi points (pumping distance is not less than 5 meters).

More durable and safer

• Battery capacity is above 5000mAh. At normal temperature, capacity of grease that can be pumped is not below 3L under action of a single battery. Its safety performance is high (Meet international safety standards such as UL1642 and UN38.3).

• It has overload protection function

Easy to maintain, more environmentally friendly

• The battery pack adopts a modular design, replacing the battery without removing the pump body.

• Grease is convenient to fill, and can be used repeatedly through the butter nozzle on the upper part of the oil tank of the pump station.

Better environmental applicability

• Good low temperature performance: the grease tank uses the springy piston structure, can effectively prevent the pumping station from being evacuated, can be applied to- 20℃ -60℃ for ambient operating conditions.

• Protection level meets IP65.

Meet the diverse needs of customers

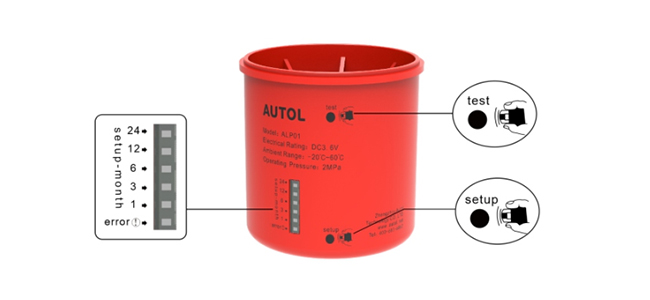

• Control modes are diversified: 5 modes (1/3/6/12/24 months) for your selection.

• Effective pump station capacity: 3 modes (500ml\250ml\120ml) for your selection.