| Product Picture |  |

|

| Model | ADP120 series | ADPB series |

| Voltage | DC24V/AC230V | DC24V |

| Output Flow | 12 ml/min | 20 ml/min |

| Reservior | 10L & 15L | 20L & 40L & 60L |

| Outlet Number | 2 pcs | 2 pcs |

| Operating Pressure | 20 MPa | 35 MPa |

| Applicable Grease | NLGI-0#,1#,2# | NLGI-0#,1#,2# |

| IP Grade | IP65 | IP65 |

| Control Mode | External/Internal Monitor | External Monitor |

| Operating Temperature | T -40 °C~70°C | T -40 °C~70°C |

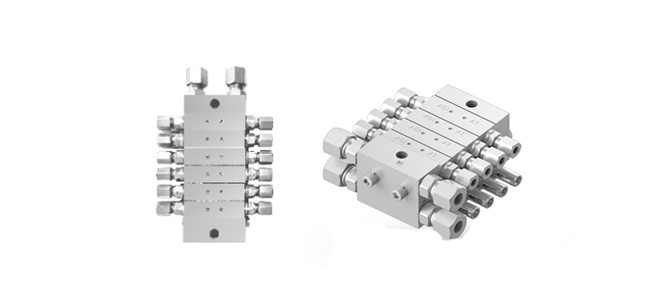

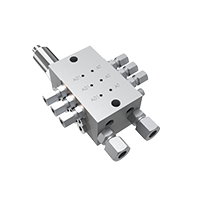

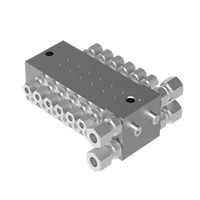

| Product Picture |  |

|

| Model | ASP series | CSP series |

| Operating Temperature | -40℃~80℃ | -40℃~80℃ |

| Outlet Flow | 0.1, 0.15, 0.2,0.4, 0.6, 0.8 & 1 mL/cy | 0.1, 0.15, 0.2,0.4, 0.6, 0.8 & 1 mL/cy |

| Number of Outlets | 2-20 | 2-20 |

| Operating Pressure | 25MPa | 25MPa |

| Applicable Grease | NLGI-0#, 1# & 2# | NLGI-0#, 1# & 2# |

| Inlet/outlet Thread | M10×1 | M10×1 |