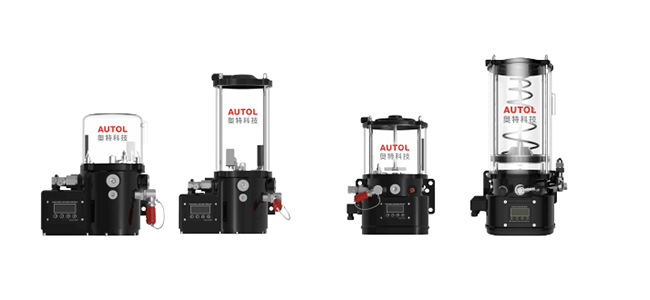

| Product Picture |  |

|

|

|

|

| Model | ALP80 series | ALPB100 series | ALPB120 | APLB132 | APLB140 |

| Voltage | DC12/24V | DC12/24V, AC230V | DC12/24V, AC230V | DC12/24V, AC230V | DC12/24V, AC230V |

| Output Flow | 1.5ml/min, 2.5ml/min, 4.5ml/min | 1.5ml/min, 2.5ml/min, 4.5ml/min | 1.5ml/min, 2.5ml/min, 4.5ml/min | 1.5ml/min, 2.5ml/min, 4.5ml/min | 1.5ml/min, 2.5ml/min, 4.5ml/min |

| Reservior | 1L & 2L | 2L & 4L | 4L & 8L & 15L & 20L | 20L & 30L | 15L & 20L & 30L |

| Max Outlet Number | 3 outlets | 4 outlets | 4 outlets | 4 outlets | 4 outlets |

| Max Pressure | 35 MPa | 35 MPa | 35 MPa | 35 MPa | 35 MPa |

| Applicable Grease | Grease below NLGI-2 | Grease below NLGI-2 | Grease below NLGI-2 | Grease below NLGI-2 | Grease below NLGI-2 |

| IP Grade | IP 6K 9K | IP 6K 9K | IP 6K 9K | IP 6K 9K | IP 6K 9K |

| Control Mode | External/Internal Monitor | External/Internal Monitor | External/Internal Monitor | External/Internal Monito | External/Internal Monito |

| Operating Temperature | T -40 °C~70°C | T -40 °C~70°C | T -40 °C~70°C | T -40 °C~70°C | T -40 °C~70°C |

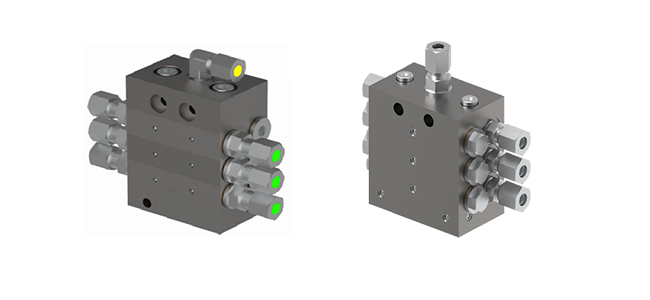

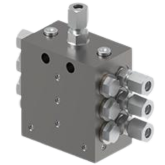

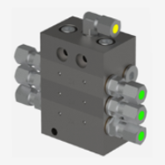

| Product Picture |  |

|

| Model | SSVA | JPQ |

| Operating Temperature | T -40 °C~80°C | T -40 °C~80°C |

| Outlet Flow | 0.2 ml/cy | 0.08, 0.16, 0.24, 0.32ml/cy 0.8, 1.04,1.28,1.6ml/cy |

| Number of Outlets | 6-22 outlets | 6-24 outlets |

| Operating Pressure | 35 MPa | 30 MPa |

| Applicable Grease | NLGI-0#,1#,2# | NLGI-0#,1#,2# |

| Inlet/outlet Thread | M10 x 1 | M10 x 1 |