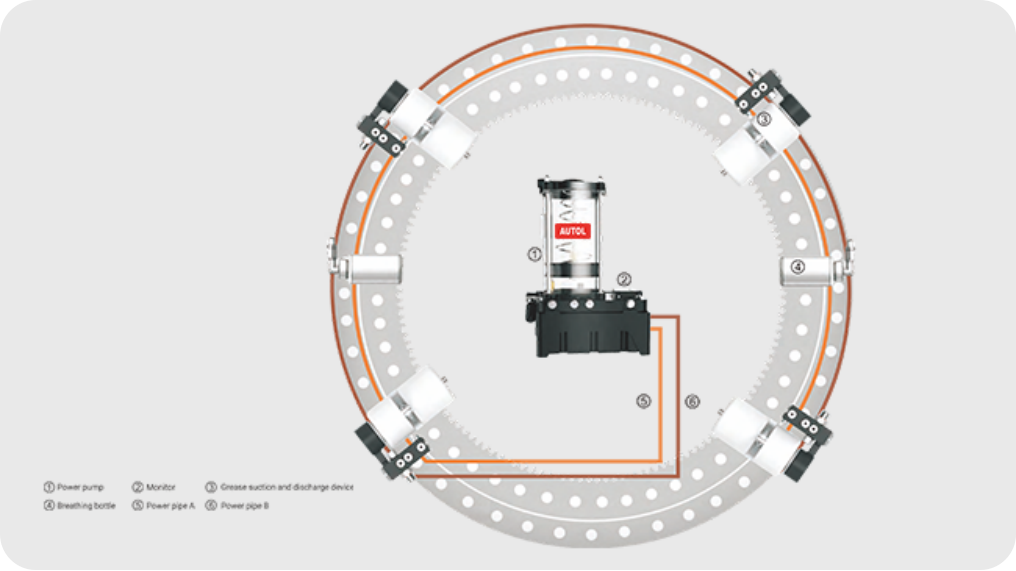

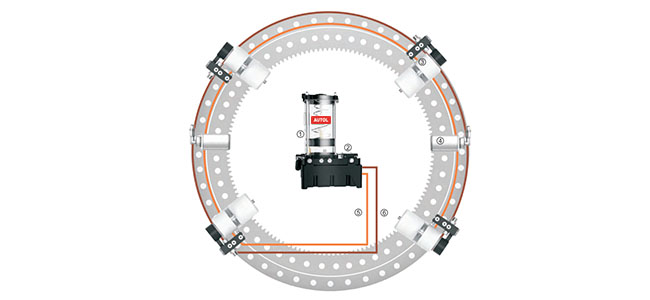

ADJ300TW refilling grease pump

The product is an electric greasing machine (referred to as a greasing machine), which is easy to operate, labor-saving and time-saving. The ADJ300TW is suitable for construction machinery, such as large excavators and rigid beam mine trucks.