overview

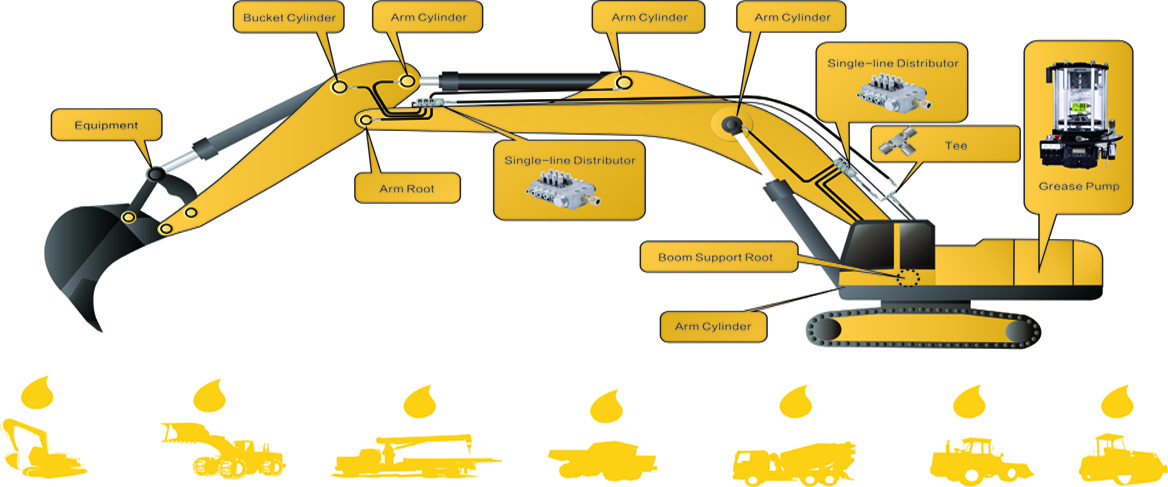

According to their moving mode, excavators can be divided into wheel type and track type. 1. Usually, an excavator has 18, 19 or 20 lube points. 2. For some excavators with lifting cabs, there are 8 lube points in bearing joints, 2 in oil tank, and 10 in

Chat nowIntroduction of Excavator Model

A single-line centralized lubrication system is used for the lubrication of a excavator. If there is something wrong, the grease pressure sensor at the end of the single-line distributor that monitors the system in real time will send fault signal and stop alarm.The lube supply for each lube point can be set according to the real need. The fault of one lube point will not cause affects on other lube points because they are connected in parallel, which is a redundancy design.

Working principle:

When the pump starts to work, lube is transmitted to the distributor through the supply line. The grease pressure sensor at the end of the distributor works and gives feedback signals. The pressure in supply line increases till safety relief pressure, making sure quantitative lubrication for each lube point. After that, the pump stops working. The pressure in supply line relieves, so does the single-line distributor assisted by auxiliary unloading valve. This round lubrication ends with lube stored for next-round.