overview

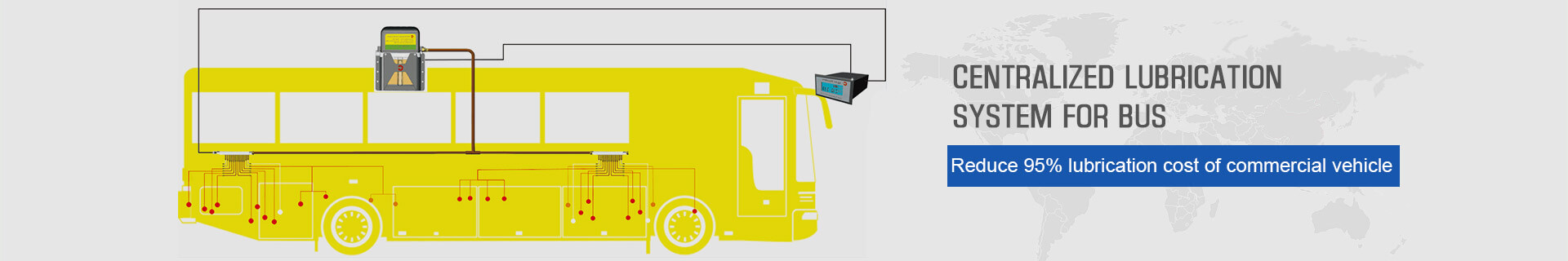

ACL300 Intelligent Multi-line Centralized Lubrication System is a high-tech product developed and manufactured by Auto Technology Co. Ltd. This lubrication system incorporates ideas of scientific distribution of grease and precise lubrication in terms of

Chat nowThe advantages of centralized lubrication system over manual lubrication:

1. Automatic system guarantees timing and automatic lubrication, which saves labor (95%) and ensures operators’ safety.

2. By forced and timing lubrication with fixed quantity for fixed points, centralized lubrication system is clean and grease-saving. Save grease for more than 70%, environmentally sustainable.

The advantages of centralized lubrication system over manual lubrication:

3. Compared to manual lubrication, centralized lubrication system is enclosed, which avoids grease leaking and the abrasion of friction pairs.

4. Your machine is well greased, which extends the service interval, thus lengthening working time and enchancing your efficiency.

5. Expand your machines’ lifespan for more than 60%.